This product is not available for new orders. We recommend ordering: 05108-L40.

| Services Available | |

|---|---|

| Repair | Yes |

| Calibration | No |

| Free Support | Yes |

Overview

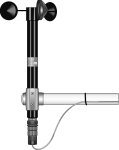

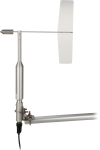

Designed for offshore and marine applications, the 05106 is a lightweight, robust instrument that measures wind speed and direction. Manufactured by R. M. Young, this wind monitor is cabled for use with Campbell Scientific data loggers.

Read MoreBenefits and Features

- Waterproof bearing lubricant and a sealed, heavy-duty cable pigtail instead of the standard junction box make it more durable at marine and off-shore locations

- Compatible with most Campbell Scientific data loggers

- Rugged enough for harsh environments

- Constructed with thermoplastic material that resists corrosion from sea-air environments and atmospheric pollutants

- Compatible with the LLAC4 4-channel Low-Level AC-Conversion Module, which increases the number of anemometers one data logger can measure

- Uses stainless-steel, precision-grade ball bearings for the propeller shaft and vertical shaft bearings

- Compatible with the CWS900-series interfaces, allowing it to be used in a wireless sensor network

This product is available for repair and calibration

Images

Detailed Description

The 05106 Wind Monitor-MA is made out of rigid UV-stabilized thermoplastic with stainless steel and anodized aluminum fittings. The thermoplastic material resists corrosion from sea air environments and atmospheric pollutants. It uses stainless-steel precision-grade ball bearings for the propeller shaft and vertical shaft bearings.

To make it more durable in offshore and marine applications, the 05106 has waterproof bearing lubricant and a sealed, heavy-duty cable pigtail instead of the standard junction box.

The 05106 measures wind speed with a helicoid-shaped, four-blade propeller. Rotation of the propeller produces an ac sine wave that has a frequency directly proportional to wind speed. The ac signal is induced in a transducer coil by a six-pole magnet mounted on the propeller shaft. The coil resides on the non-rotating central portion of the main mounting assembly, eliminating the need for slip rings and brushes.

Wind direction is sensed by the orientation of the fuselage-shaped sensor body, which is connected to an internal potentiometer. The data logger applies a known precision excitation voltage to the potentiometer element. The output is an analog voltage signal directly proportional to the azimuth angle.

Similar Products

Compatibility

Please note: The following shows notable compatibility information. It is not a comprehensive list of all compatible products.

Data Loggers

| Compatible | Note | |

|---|---|---|

| 21X (retired) | ||

| CR10 (retired) | ||

| CR1000 (retired) | ||

| CR1000X (retired) | ||

| CR10X (retired) | ||

| CR200X (retired) | ||

| CR206X (retired) | ||

| CR23X (retired) | ||

| CR295X (retired) | ||

| CR300 (retired) | ||

| CR3000 (retired) | ||

| CR310 | ||

| CR500 (retired) | ||

| CR5000 (retired) | ||

| CR510 (retired) | ||

| CR800 (retired) | ||

| CR850 (retired) | ||

| CR9000 (retired) | ||

| CR9000X (retired) |

Additional Compatibility Information

Data Logger Considerations

The 05106-L is compatible with most of our data loggers.

Specifications

| Operating Temperature Range | -50° to +50°C (assuming non-riming conditions) |

| Mounting Pipe Description |

|

| Propeller Diameter | 18 cm (7.1 in.) |

| Overall Height | 37 cm (14.6 in.) |

| Overall Length | 55 cm (21.7 in.) |

| Main Housing Diameter | 5 cm (2.0 in.) |

| Weight | 1.5 kg (3.2 lb) |

Wind Speed |

|

| Range | 0 to 100 m/s (0 to 224 mph) |

| Accuracy | ±0.3 m/s (0.6 mph) or 1% of reading |

| Starting Threshold | 1.1 m/s (2.4 mph) |

| Distance Constant | 2.7 m (8.9 ft) 63% recovery |

| Output |

ac voltage (three pulses per revolution) 90 Hz (1800 rpm) = 8.8 m/s (19.7 mph) |

| Resolution | (0.0980 m s-1)/(scan rate in seconds) or (0.2192 mph)/(scan rate seconds) |

Wind Direction |

|

| Mechanical Range | 0 to 360° |

| Electrical Range | 355° (5° open) |

| Accuracy | ±3° |

| Starting Threshold | 1.1 m/s (2.4 mph) at 10° displacement |

| Distance Constant | 1.3 m (4.3 ft) 50% recovery |

| Damping Ratio | 0.3 |

| Damped Natural Wavelength | 7.4 m (24.3 ft) |

| Undamped Natural Wavelength | 7.2 m (23.6 ft) |

| Output |

|

| Voltage | Power switched excitation voltage supplied by data logger |

Related Documents

Product Brochures

Manuals

Videos & Tutorials

FAQs for

Number of FAQs related to 05106-10: 13

Expand AllCollapse All

-

Campbell Scientific does not sell an extension cable. A replacement cable can be ordered and built to the desired length (pn 05106CBL-L). This replacement cable has a connector that mates with the connector at the end of the 3 ft cable attached to the 05106-L.

-

The measurement instructions will likely remain the same. However, in addition to the multiplier and offset, the type of pulse may change for the wind speed, and the excitation voltage may change for the wind direction. For an explanation of how the data logger needs to be programmed, see the instruction manual.

-

This depends on what is broken. Typically, Campbell Scientific can repair the unit, and the user does not have to purchase a new one.

-

The short answer is less than 0.01 mA. The wind speed signal requires no power. The wind direction portion of the sensor only uses a maximum of 0.5 mA when excited with 5 Vdc, and then it is only on for 0.016 s for every measurement. When the wind direction is measured every second (typical), the average current drain is less than 0.01 mA.

-

Orientation of the wind monitor is done after the data logger has been programmed, and the location of True North has been determined. True North is usually found by reading a magnetic compass and applying the correction for magnetic declination, where magnetic declination is the number of degrees between True North and Magnetic North. Magnetic declination for a specific site can be obtained from a USFA map, local airport, or through a computer service.

-

The information included on a calibration sheet differs with each sensor. For some sensors, the sheet contains coefficients necessary to program a data logger. For other sensors, the calibration sheet is a pass/fail report.

-

Most Campbell Scientific sensors are available as an –L, which indicates a user-specified cable length. If a sensor is listed as an –LX model (where “X” is some other character), that sensor’s cable has a user-specified length, but it terminates with a specific connector for a unique system:

- An –LC model has a user-specified cable length for connection to an ET107, CS110, or retired Metdata1.

- An –LQ model has a user-specified cable length for connection to a RAWS-P weather station.

If a sensor does not have an –L or other –LX designation after the main model number, the sensor has a set cable length. The cable length is listed at the end of the Description field in the product’s Ordering information. For example, the 034B-ET model has a description of “Met One Wind Set for ET Station, 67 inch Cable.” Products with a set cable length terminate, as a default, with pigtails.

If a cable terminates with a special connector for a unique system, the end of the model number designates which system. For example, the 034B-ET model designates the sensor as a 034B for an ET107 system.

- –ET models terminate with the connector for an ET107 weather station.

- –ETM models terminate with the connector for an ET107 weather station, but they also include a special system mounting, which is often convenient when purchasing a replacement part.

- –QD models terminate with the connector for a RAWS-F Quick Deployment Station.

- –PW models terminate with the connector for a PWENC or pre-wired system.

-

Not every sensor has different cable termination options. The options available for a particular sensor can be checked by looking in two places in the Ordering information area of the sensor product page:

- Model number

- Cable Termination Options list

If a sensor is offered in an –ET, –ETM, –LC, –LQ, or –QD version, that option’s availability is reflected in the sensor model number. For example, the 034B is offered as the 034B-ET, 034B-ETM, 034B-LC, 034B-LQ, and 034B-QD.

All of the other cable termination options, if available, are listed on the Ordering information area of the sensor product page under “Cable Termination Options.” For example, the 034B-L Wind Set is offered with the –CWS, –PT, and –PW options, as shown in the Ordering information area of the 034B-L product page.

Note: As newer products are added to our inventory, typically, we will list multiple cable termination options under a single sensor model rather than creating multiple model numbers. For example, the HC2S3-L has a –C cable termination option for connecting it to a CS110 instead of offering an HC2S3-LC model.

-

- Using Short Cut, click the applicable wind direction sensor in the Selected Sensors list of the Outputs screen.

- The two output options enabled are Sample and WindVector. Select WindVector.

- The WindVector instruction has output options. Select an option with mean wind direction in it.